Hi everyone! There has been so much progress since my last blog entry. It’s really getting exciting as the barn takes shape and it actually looks like a barn. In my last blog post, I talked about the roof being put on the indoor and the barn being framed up and roof put on. Dave Wisner of K and L Contracting had started the excavation around the outside of the barn.

It is so busy around here during the week that when the weekend hits, it actually seems too quiet! Once Dave had the outside of the barn excavated and any rain water was directed away from the barn and indoor, he began working on the base for the indoor. I can’t even begin to tell you how many dump-truck loads of stone dust and rock were delivered! It seemed like there were several trucks in here daily.

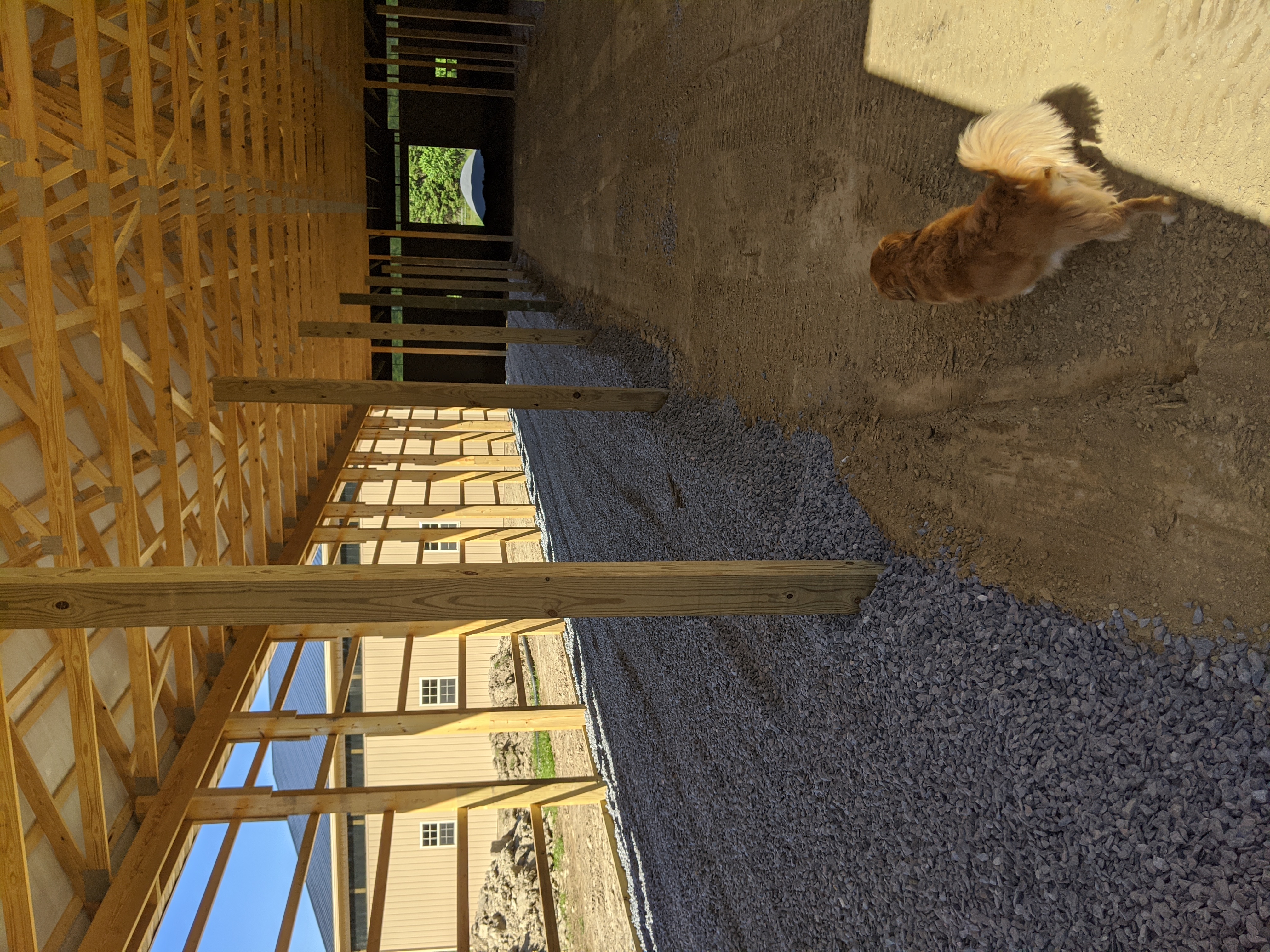

To begin the process of putting in the base for the indoor, Dave had to dig down and remove a couple inches of topsoil. This soil was moved outside to be used around the back of the barn. Dave then leveled the soil and then several inches of rock were dumped and spread, then he used the roller to level and tamp them into place. On top of that he put down several inches of very fine stone dust. At every step of this process, he used a laser level to make sure it was level and perfect. Once the stone dust was in place, he used the roller many, many times to make sure that it was really locked into place. It was so fun to walk in there and see it actually looking like an indoor! Dave also put rock down in the barn to build a base for the stalls and concrete in the aisleway.

While Dave was working on the base in the indoor, the builders were busy framing up the stalls, tack room, feed room, grooming stall and wash stall. I have included pictures of this. I was amazed at how much bigger the barn looked after the stalls were framed up. We have an extra wide aisle way, which I love as there is enough room to keep tack boxes in front of the stalls to keep the tack room a little more open, as it’s not very big.

As soon as Dave got the base installed, it was a good time for the builders to get in there to install the kickwall. This was a quick process—it only took about 2 days. And if I thought it looked great before this, it looked even better afterwards! I can’t wait to ride in it!

Early Monday morning on June 22, a truck arrived with two big bales of fiber for the footing. As a dressage rider, you can imagine how excited I was to see this! I did quite a bit of research on the footing I wanted and Dave was a big help, as he deals with a lot of different kinds of footing.

Dave advised us not to use what I had originally chosen. There are a lot of different factors to consider when choosing footing. For example: What base do you have? How will you groom it? How many horses will be on it daily? What discipline do you train?

One of the benefits of going to different facilities to teach is that I get to see a lot of different riding surfaces and see how it feels and how it performs, horse after horse. I also talked to friends and colleagues in the business to get advice and pros and cons of their footing. We chose FICS of Maryland. We liked that we were also staying with someone who was fairly close in case we had problems or needed anything else in the future. Sandy Hart Long is the owner and she has been wonderful to work with. She answered all of our questions and provided us with information on her product. She always returned phone calls and emails quickly, which we learned to really appreciate in this process! We chose Equifibre Footing with FICS light/intermediate Summit Blend. The sand arrived later that afternoon and I have never been so excited about sand! It is a beautiful light color and soft and just downright pretty! Dave moved it into the indoor to hold it until he spreads it out, which we are waiting to do until the electricians are finished wiring for lights in the indoor as they will have to drive trucks in there.

One of the things I have eagerly been waiting for are the stall doors and stall fronts. Jeff Byler, who was the person we met with many times when we were planning the barn and indoor, said he had custom stall fronts and doors made by the Amish. Almost two years ago, I remember him saying to me “They do great work. Are you good with going with them or do you want something specific?” So, being that I just wanted a barn, I would have agreed to anything! So I said yes.

You can imagine that I had no idea what the doors would look like. I was hoping they would be nice and considering that all the work that Byler has done so far has been wonderful, I shouldn’t have been surprised that when the stall doors came, they exceeded our expectations! It was early morning when the truck pulled in. I was leaving early to teach a clinic that day, but I was able to take a peek on the truck. They were absolutely beautiful! The colors and the craftsmanship are top notch. They were even nicer than I had imagined. I can’t wait to see the stall fronts now! They should be here in a week or so, so stay tuned for the next blog.

Oh and in all of this craziness of building a barn and working and doing life, we got a puppy! I mean, why not? We always said that when we had our farm, we would have another Jack Russell Terrier. We named her Pippin and she fits into our little zoo perfectly. I’m including pics because, well, who doesn’t love a puppy?! Happy Fourth of July everyone!

Kelly McGinn is an FEI rider, trainer and coach. She has brought many horses and riders up through the levels and has enjoyed success in regional and national championships as well as year end awards. Kelly was also chosen to ride the Friesian stallion Lolke 372 in the opening ceremonies of the World Equestrian Games in 2010 in the famed 10 horse Friesian train. Kelly has trained with Scott Hassler since 1991 and she credits Scott for her teaching and training style as he has been a big influence in her education. Kelly has also had the opportunity to ride with many well known clinicians including Steffen Peters, Michael Klimke and Debbie McDonald. Kelly also participated in the Young Dressage Trainers Symposium for 9 years where she developed a love for the process of training young horses. She runs a small teaching and training business in Easton, Maryland, where she has a variety of different horses in training and believes that every horse can benefit from good dressage training regardless of the breed.